BÜRSTENLOSEN MOTOR

BÜRSTENLOSEN MOTOR

NOVADAR INNOVA designs and manufactures brushless motors to be powered by both for dc / ac and dc / dc converters. These motors can be supplied with or without the control electronics.

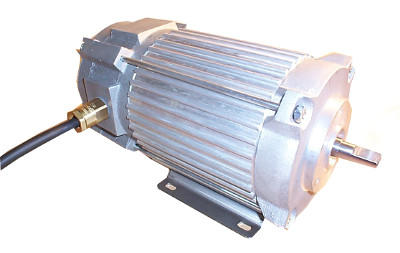

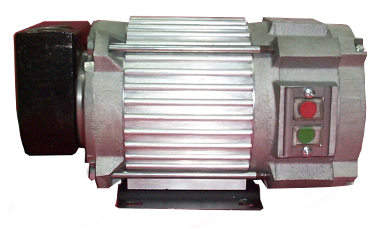

In addition to industrial applications, ventilation, brushless motors are ideal for traction and mobility applications (such as bicycles, motorcycles, cars), since they offer great power with a very low weight, in addition to being able to offer maximum torques much higher, compared to classic induction motors, they can be equipped both with and without fan depending on their destination or final field of application. The constructive format is similar to that of IEC motors types 63, 90 and 112, these motors can be made with extruded casing and the electronics included inside for types 63, 80 and 90.

NOVADAR INNOVA has developed an electric motor for light vehicles with a nominal torque of 32 Nm, maximum torque of 100 Nm, a nominal power of 11 kW, a voltage of 48 V dc, a nominal consumption of 200 A and an efficiency of 93% .

This motor stands out for its high performance at the work point, which makes it ideal for taking advantage of the energy supplied by the batteries, thus minimizing their weight and optimizing the space-autonomy binomial. It can also be adapted to the necessary interfaces in terms of power transmission and frame anchorage.

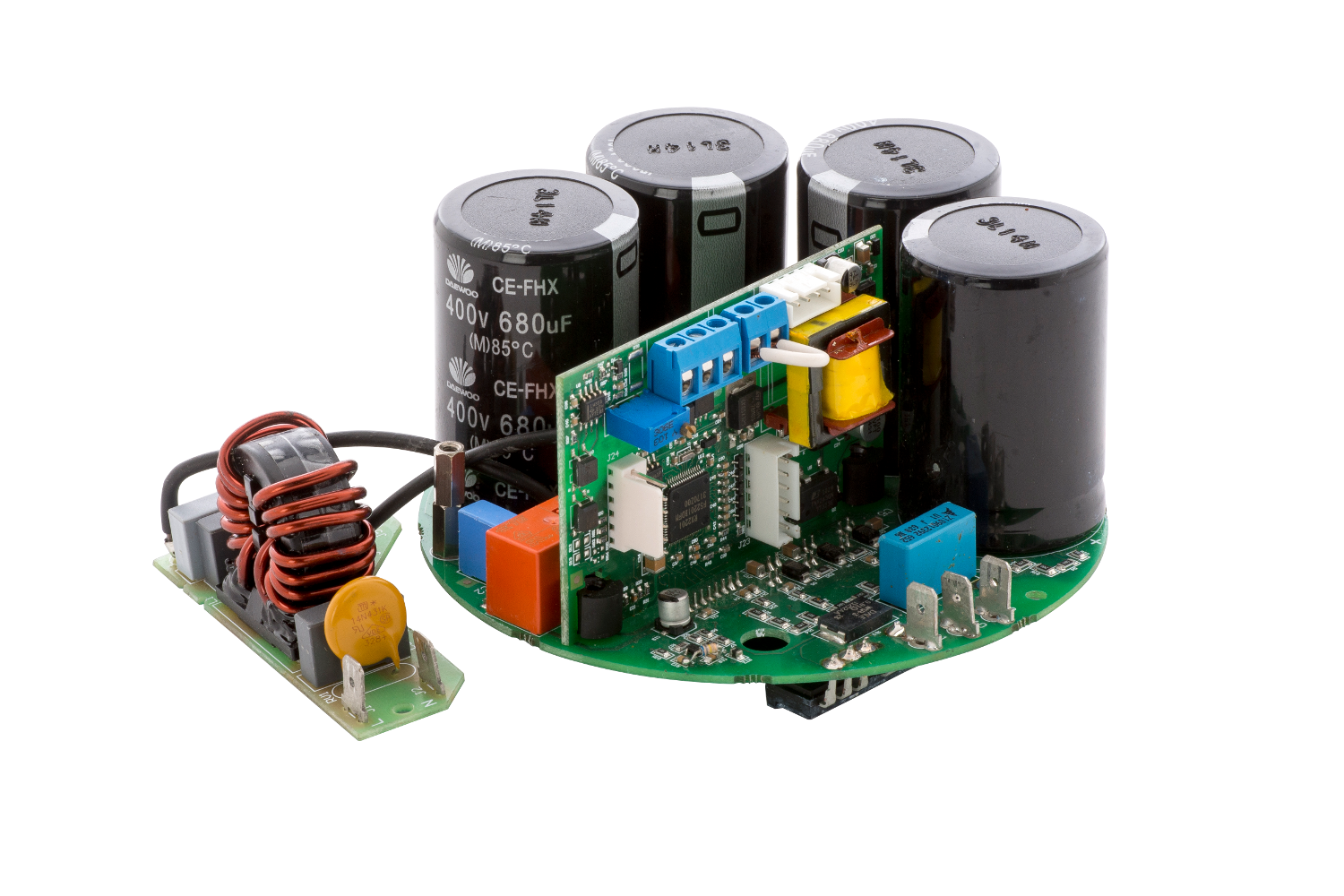

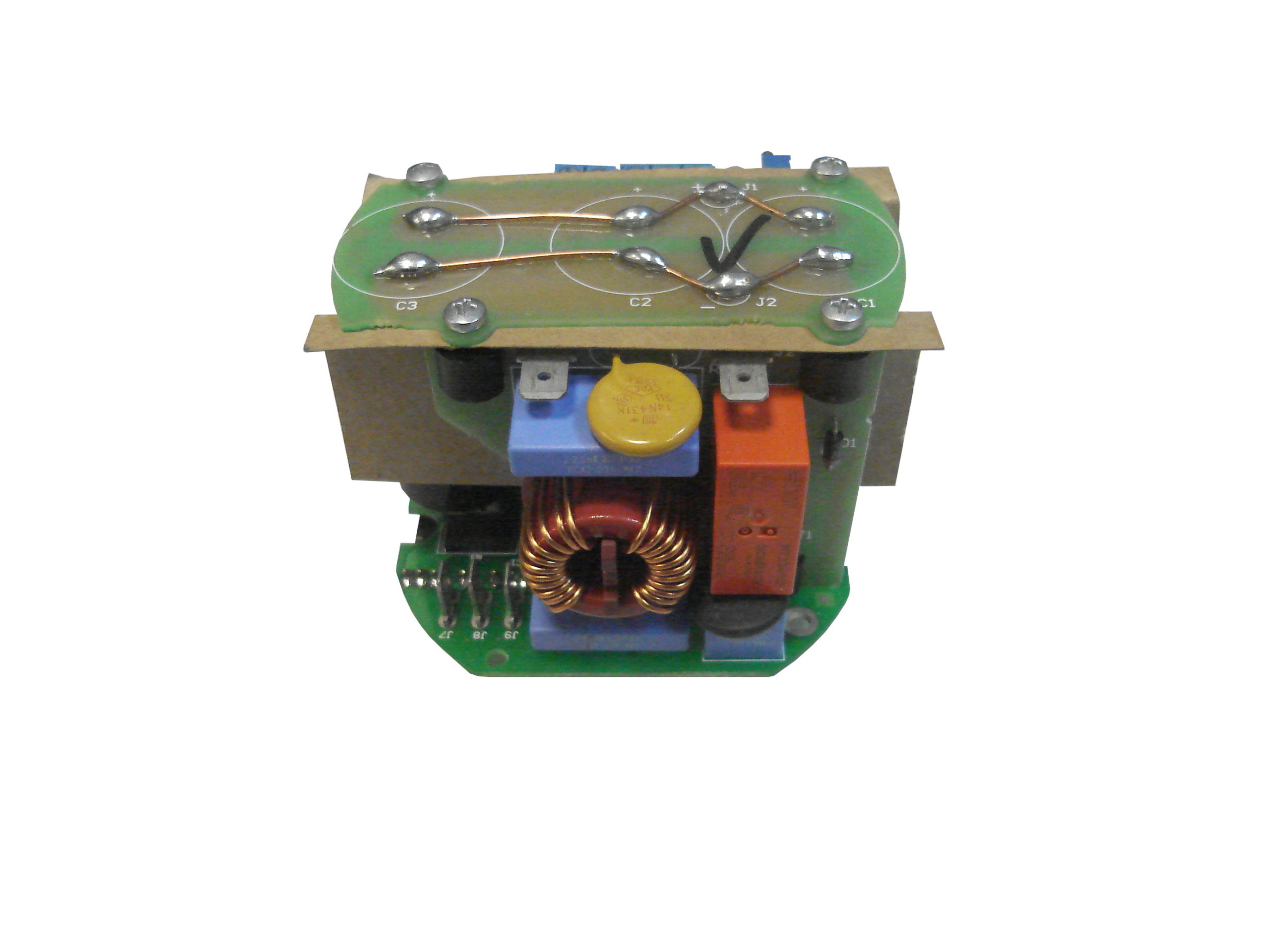

NOVADAR INNOVA offers the kit composed of the motor equipped with its corresponding Hall sensors and the associated control electronics, which includes the appropriate electrical and temperature protections to constitute a safe, reliable and robust system.

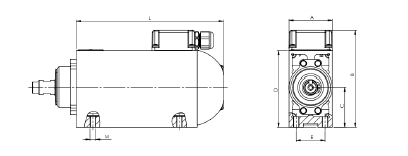

The 4 and 8-pole brushless, sensorless or PMSM motors with permanent magnet rotor manufactured by NOVADAR INNOVA guarantee high power with low weight, the reluctance torque (cogging) is minimal, ideal for traction motors with high peak torques throughout the entire speed range.

TECHNICAL CHARACTERISTICS

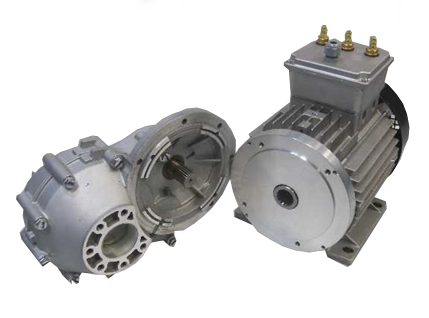

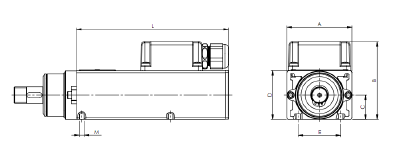

Motor PMSM T.90/8 8kW 4500rpm with reducer

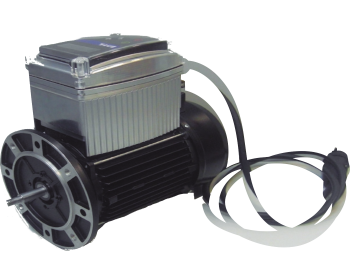

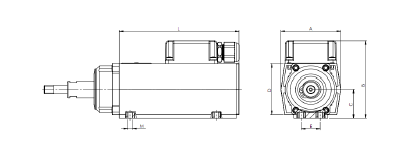

Motor PMSM T.90/8 1.5kW 4500 rpm B5 with brake

Motor PMSM T.112/8 15kW 3750 rpm with forced ventilation

Motor PMSM T.112 / 8 15 kW 3750 rpm with forced and reducing ventilation for forced and reducing ventilation

Motor PMSM T.90/8 8kW 4500rpm

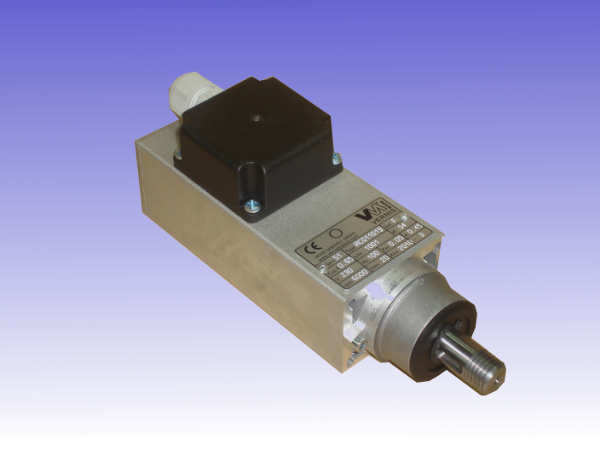

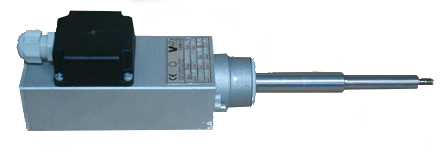

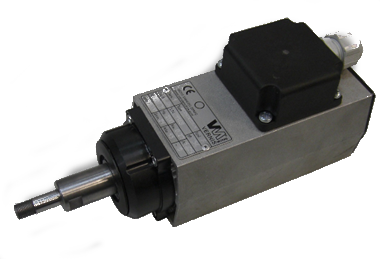

Motor T.56/4 500W 30Nm 200 rpm Includes epicyclic reducer

High efficiency brushless motor with permanent magnets mounted in extruded housing with flange mounting B14

High efficiency brushless motor with permanent magnets and IEC standard B5 flange fixing, controlled by built-in electronics.

USES FOR:

Electric car

Electric Taxi

Post car

Golf Cars

Electric Pallet trucks

TABLE OF MODELS

Neueste Kommentare