IEC MOTORS

SINGLE PHASE IEC MOTORS

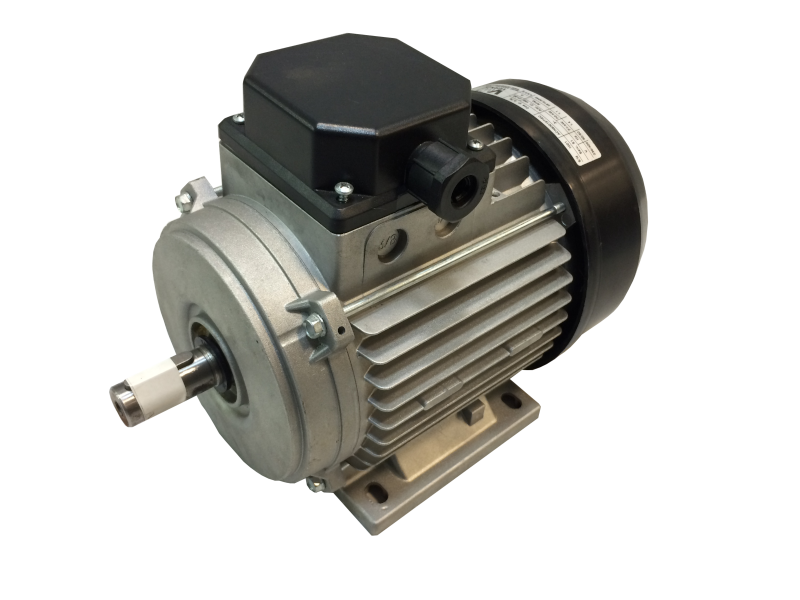

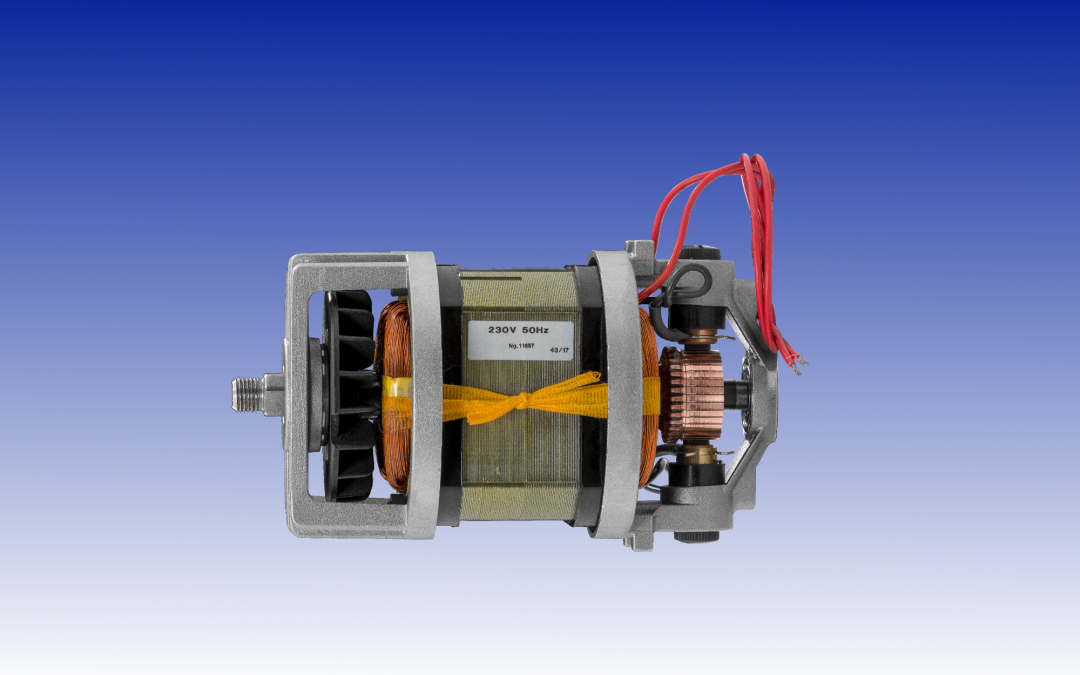

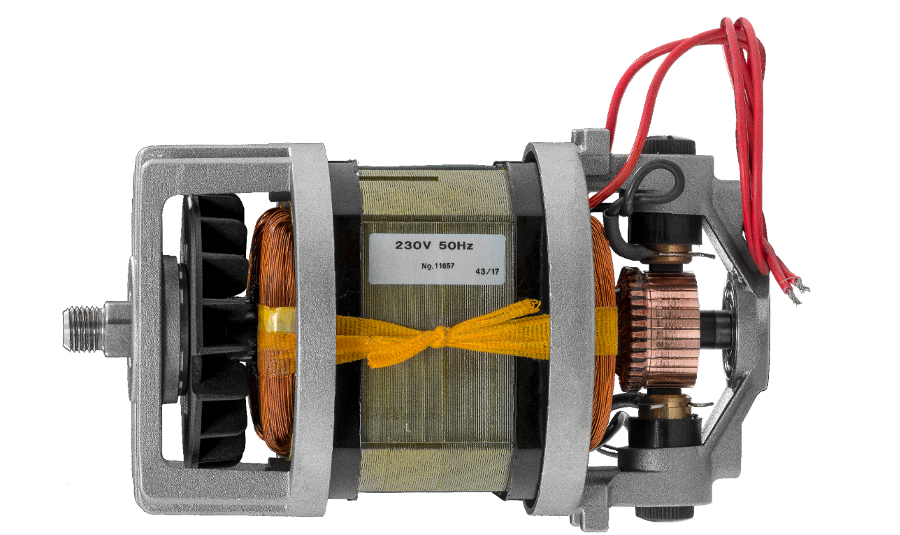

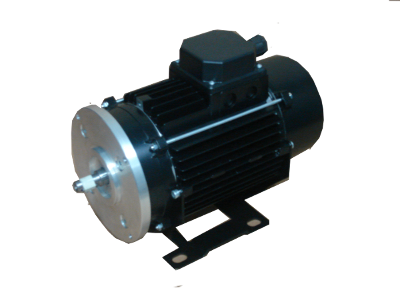

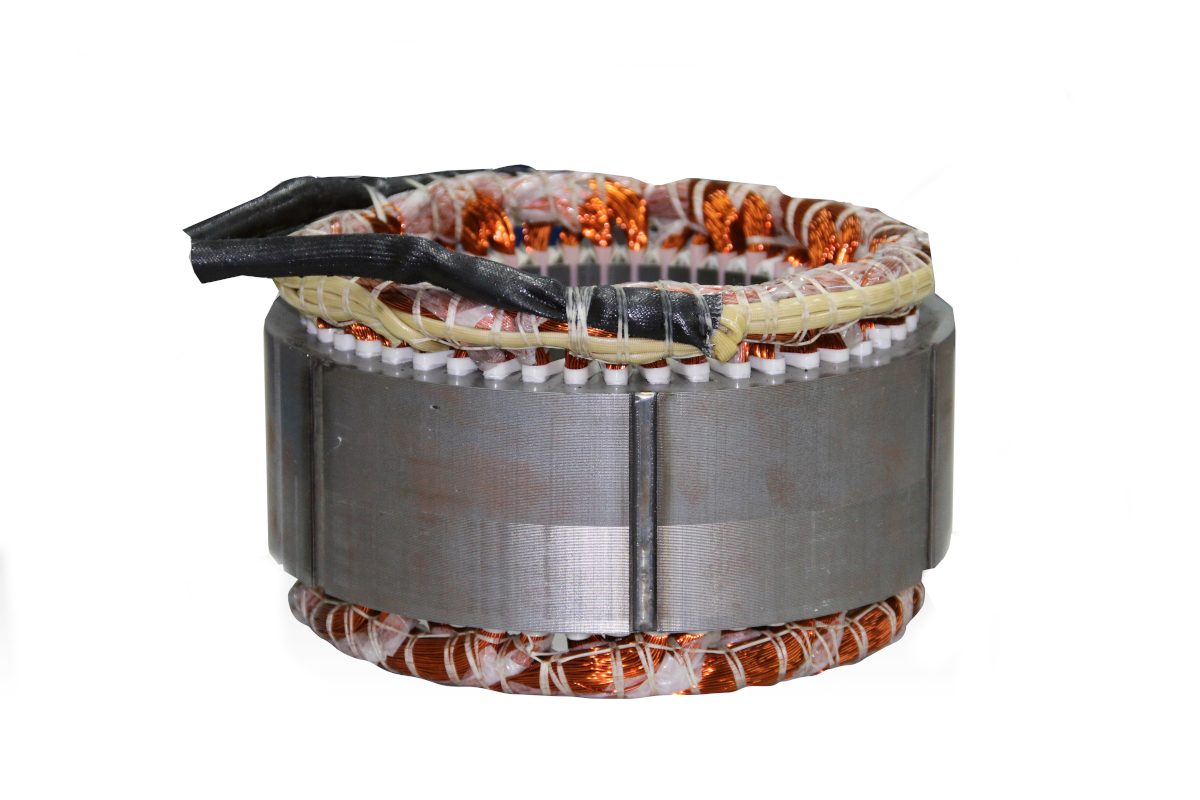

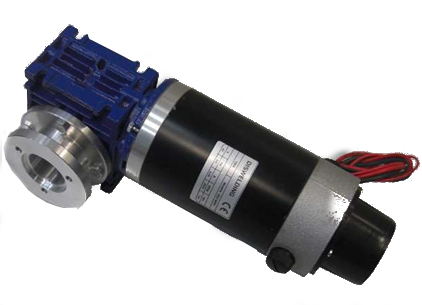

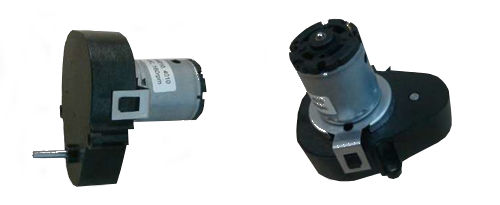

NOVADAR INNOVA designs and manufactures a wide variety of single phase electric motors from parell d’arrencada mitjà. The IE1 single phase electric motors are assembled on B3, B5 and B14 type flanges and have a rear cover to avoid the entry of foreign particles, water, oli or pols into the interior of the motor.

The protection rating is IP-55 and the rating is F-EFF2 class. Aquests motors elèctrics monophasics come completely tancats and compete with outdoor ventilation. The treball voltage is 230V.

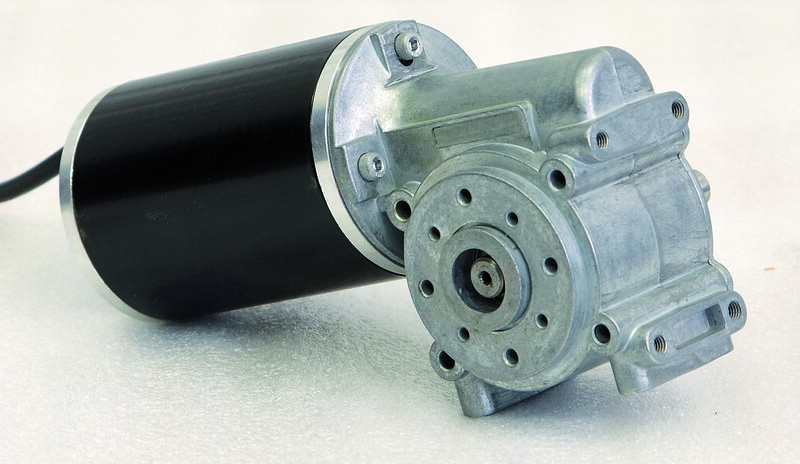

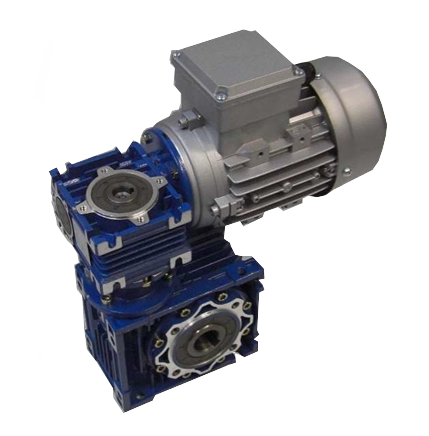

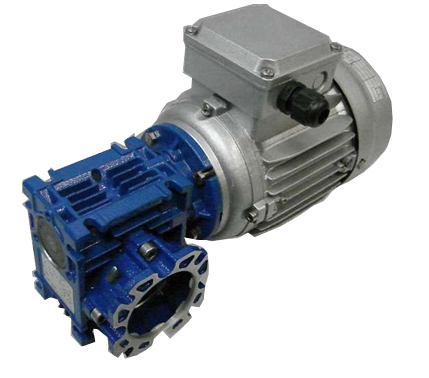

Motor IEC with flange B5

Motor IEC with flange B3

TABLE OF MODELS

Electric Motors IE 1

IE1 Single Phase 2 poles / 50 Hz. 230V

IE1 single phase 4 poles / 50 Hz. 230V

IE1 single phase 6 poles / 50Hz. 230V

IE1 monofasicos 6 polos / 50Hz. 230V( Duplicate )

IE1 single phase 8 poles / 50Hz. 230V

Electric Motors IE 2

IE2 single phase 2 poles / 50Hz. 230V

IE2 single phase 4 poles / 50 Hz. 230V

IE2 single-phase 6 poles / 50 Hz. 230V

IE2 single-phase 8 poles / 50 Hz. 230V

Electric Motors IE3

IE3 single-phase 2 poles / 50 Hz. 230V

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

IE3 single-phase 4 poles / 50 Hz. 230V

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

IE3 single-phase 6 poles / 50 Hz. 230V

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

IE3 single-phase 8 poles / 50 Hz. 230V

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Recent Comments