GEARED MOTORS

GEARED MOTORS

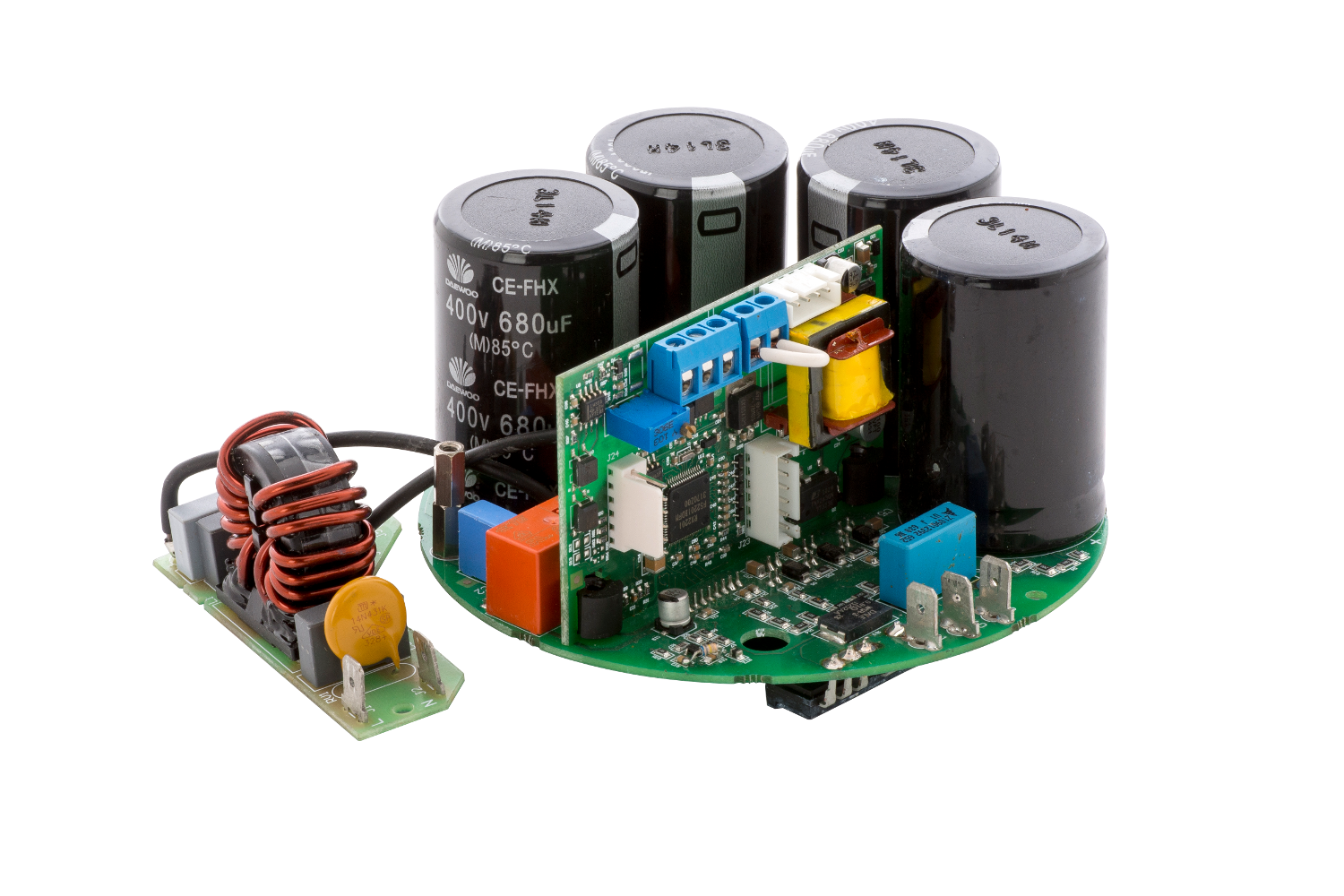

NOVADAR INNOVA has an extensive range of geared motors for many applications among which are: vending, fluid transfer, laboratory equipment, electrical appliances, automatic doors, etc.. The power of these units can be both AC and DC, there are endless possibilities for the output speed of the gearbox and torque required.

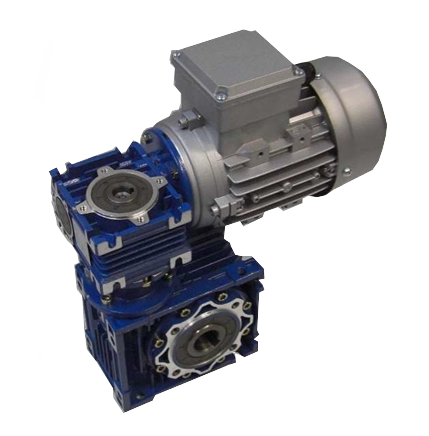

Combined crown-worm gear motors: According to the indications of our clients, at NOVADAR INNOVA we carry out special assemblies such as combined crown-worm gear motors that consist of two speed reducers that are coupled to achieve greater and higher speed reductions. It is a very simple and inexpensive solution, but in this type of assembly a decrease in performance must be anticipated.

Worm gearmotors and standard execution: Both in the standard worm gearmotors and in the combined version, the assembly is carried out with motors of special manufacture requested by the customer or according to the IEC standard. Assemblies made in NOVADAR INNOVA are delivered with a B14 or B5 flange. (Consult other flanges)

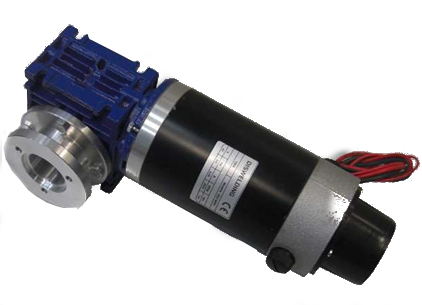

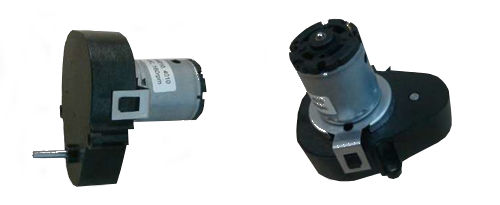

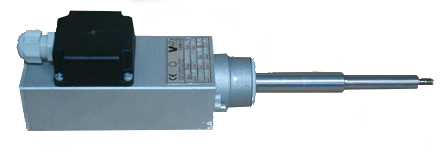

DC geared motor with tachometric dynamo: Due to the great demand in the market, NOVADAR INNOVA has developed motors with speed regulated by tachometric dynamo. Also, and at the request of our clients, we develop applications with hall or encoders.

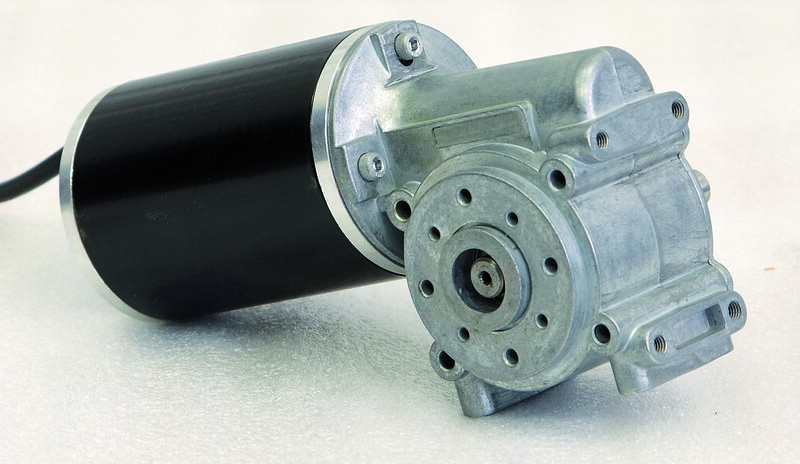

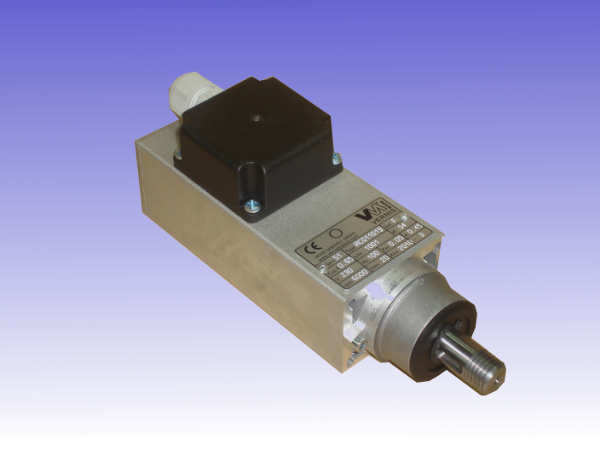

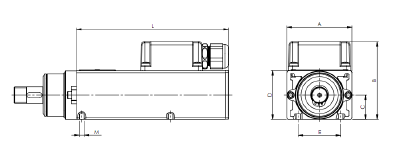

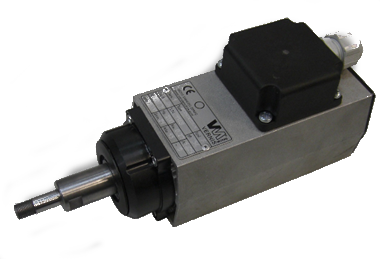

Motor reductor RM-Motor CC

Accionat per motor de CC; Parell màxim del reductor: 80Ncm.

RM900 -motor CC

Potència : 3,3W

Freqüència: 50Hz

Velocitat: 6.800 rpm

RM900 – motor CC

Potència: 6,6W

Freqüència: 50Hz

Velocitat: 7.000 rpm

Nota: En aplicacions amb reduccions elevades, haurà de reduir les prestacions de sortida un 10% a causa de la disminució del rendiment del propi reductor

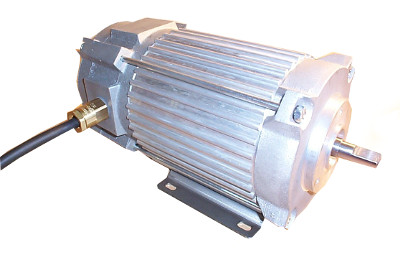

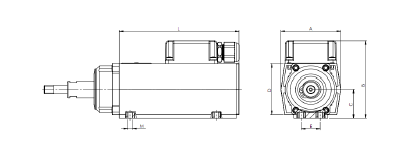

Motor reductor RC-Motor AC

Accionat per motor d’AC; Parell màxim del reductor: 300Ncm

RC 920 -motor AC

Potència :9W

Freqüència:50Hz

Velocitat: 2.750 rpm

RC 940 -motor AC

Potència :15W

Freqüència:50Hz

Velocitat: 2.800 rpm

RC 960 -motor AC

Potència :15W

Freqüència:50Hz

Velocitat: 2.800 rpm

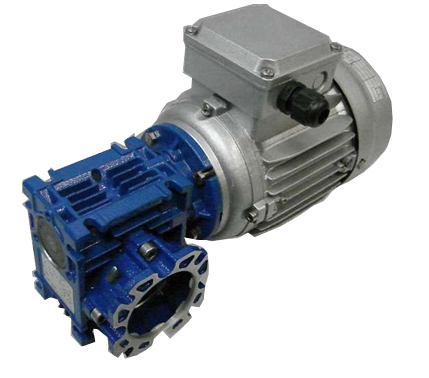

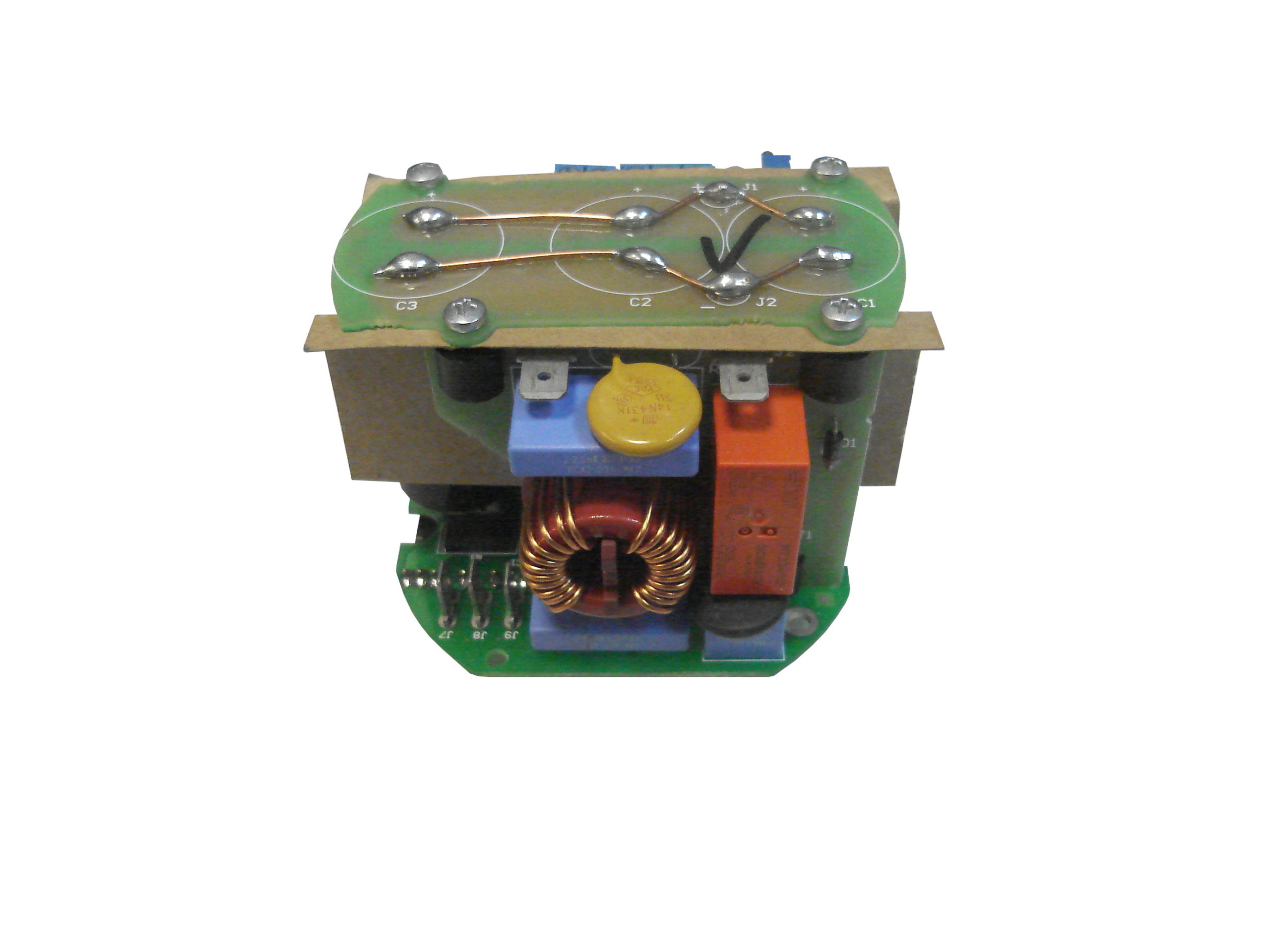

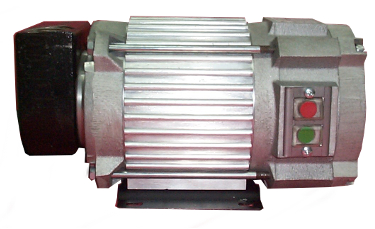

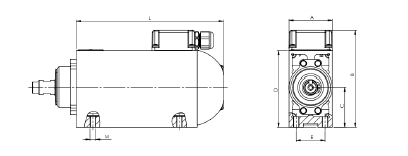

Motor reductor RD-Motor AC

Accionat per motor de C.A; Parell màxim del reductor: 150Ncm.

RD915 – motor AC

Potència: 7W

Freqüència: 50Hz

Velocitat: 2. 700 rpm

RD920 – motor AC

Potència: 9W

Freqüència: 50Hz

Velocitat: 2. 750 rpm

Recent Comments